- 您现在的位置:买卖IC网 > Sheet目录2000 > IDTNW6005ASG (IDT, Integrated Device Technology Inc)IC CALLER ID DECODER 20SOIC

13

INDUSTRIAL TEMPERATURE RANGE

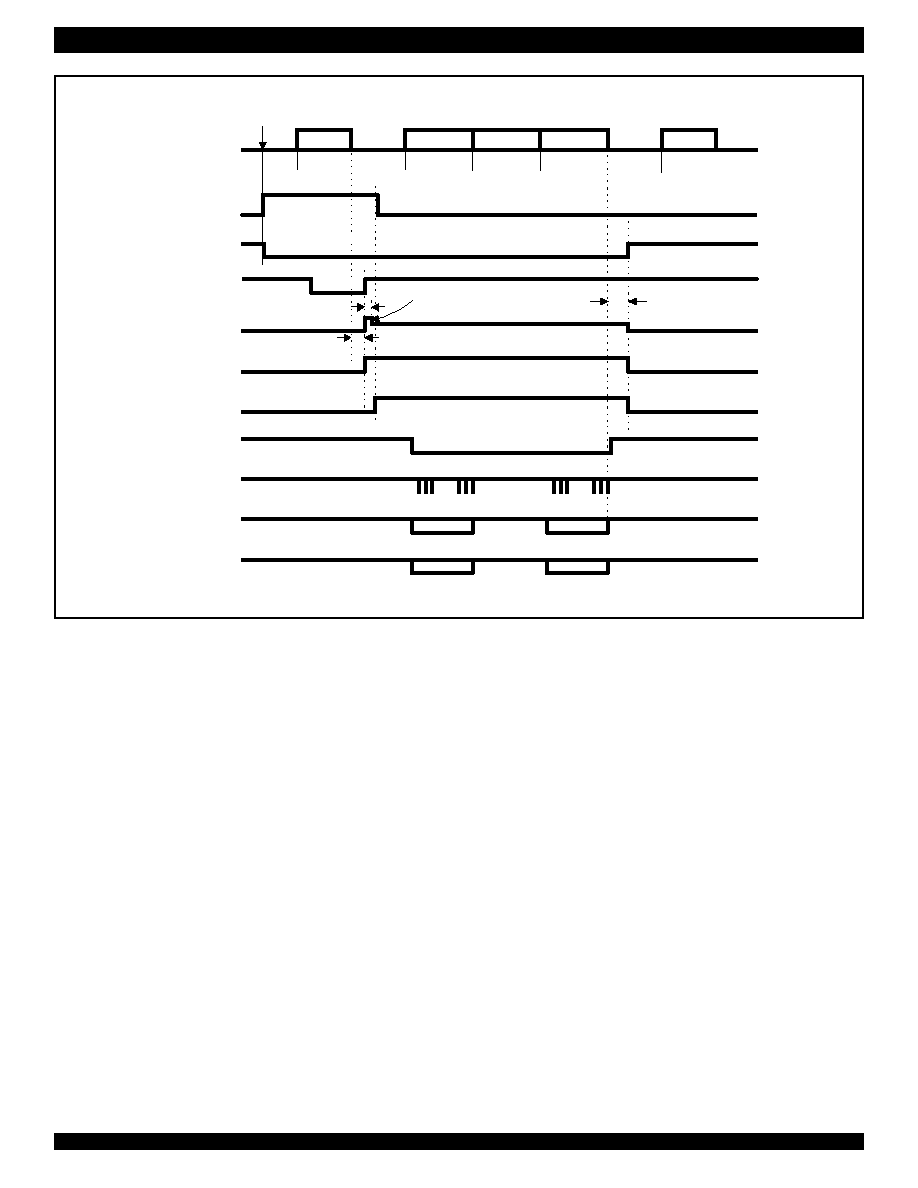

NW6005 ENHANCED TYPE II CALLER ID DECODER

Alerting

Signal

Ch. Seizure

Mark

Message

Ring

..101010..

Data

...

A

B

C

D

E

F

G

Line Reversal

A/B Wires

PWDN

STD

TE DC load

TE AC load

FSKEN

CD

DR

DCLK

DATA

15 ±1 ms

20 ±5 ms

<120

A

50 - 150 ms

< 0.5 mA (optional)

Current Wetting Pulse

Zss

Tip/Ring

DT-ASEN

Note 1

Note 2

Note 3

Note 4

Notes:

1) A

≥ 100ms, B=88 - 110 ms, C≥ 45 ms (up to 5 sec), D= 80 -262 ms, E= 45 - 75 ms, F≤ 2.5 sec (typ. 500 ms), G≥ 200 ms.

2) By choosing t

GA=15 ms, tABS will be 15-25 ms (refer to Fig. 8). Current wetting pulse and AC/DC load should be applied right after the

STD rising edge.

3) AC and DC loads should be removed between 50-150 ms after the end of the FSK signal. The NW6005 may go to power down mode

to save power.

4) FSKEN should be set low to disable the FSK demodulator, when the FSK signal is not expected.

5) Tip/Ring DT-ASEN, PWDN and FSKEN are internal signals decoded from Control Bits CB2-0.

6) When CB0 is low, both DR and DCLK pins are unused.

Figure 13. BT Idle State (on-hook) Data Transmission Timing Diagram

Note 5

Note 6

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

IDTNW6006AS

IC CALLER ID DECODER 20-SOIC

IDTSSTE32882HLBBKG

IC REGISTERING CLK DRIVER 176BGA

IDTSSTE32882KA1AKG

IC REGISTERING CLK DRIVER 176BGA

ISD1750SYR

IC VOICE REC/PLAY 50SEC 28-SOIC

ISD5008EYI

IC VOICE REC/PLAY 4-8MIN 28-TSOP

ISL12008IB8Z

IC RTC I2C LO-POWER 8-SOIC

ISL12020MIRZ-T7A

IC RTC/CALENDAR TEMP SNSR 20DFN

ISL12022IBZ-T7A

IC RTC/CALENDAR TEMP SNSR 8SOIC

相关代理商/技术参数

IDTNW6006AS

功能描述:IC CALLER ID DECODER 20-SOIC RoHS:否 类别:集成电路 (IC) >> 接口 - 编码器,解码器,转换器 系列:- 产品变化通告:Development Systems Discontinuation 26/Apr/2011 标准包装:1 系列:- 类型:编码器 应用:DVB-S.2 系统 电压 - 电源,模拟:- 电压 - 电源,数字:- 安装类型:- 封装/外壳:模块 供应商设备封装:模块 包装:散装 其它名称:Q4645799

IDTP62000NLG

制造商:Integrated Device Technology Inc 功能描述:IC PWM CTRLR 2/3/4-PHASE 64QFN

IDTP62000NLG8

制造商:Integrated Device Technology Inc 功能描述:IC PWM CTRLR 2/3/4-PHASE 64QFN

IDTP63131-00NDGI

制造商:Integrated Device Technology Inc 功能描述:IC BUCK CTRLR MULTI-PH 40QFN

IDTP63131-00NDGI8

制造商:Integrated Device Technology Inc 功能描述:IC BUCK CTRLR MULTI-PH 40QFN

IDTP63133-00NDGI

制造商:Integrated Device Technology Inc 功能描述:IC BUCK CTRLR MULTI-PH 40QFN

IDTP63133-00NDGI8

制造商:Integrated Device Technology Inc 功能描述:IC BUCK CTRLR MULTI-PH 40QFN

IDTP67001EXG

制造商:Integrated Device Technology Inc 功能描述:IC MOSFET DVR 1PH VR12 8SOIC